Specifications of polyurethane molds

Specifications of professional polyurethane molds for the production of manufactured stone by Art-Stone Company

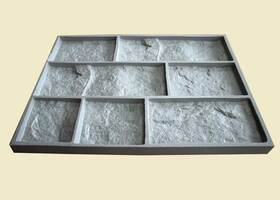

Our company has long successfully produced and sold high-precision molds for professional production of manufactured facing stone. Today our catalog of molds is represented by more than 40 various reliefs. Both planar and angular molds are available.

|

|

|

Nowadays the Internet is full of ads of various kinds of molds made from a wide variety of materials. Be aware that many of those molds do not meet the requirements set for the production of high-quality and aesthetically convincing products. The fact is that there are several indicators assessing the suitability and class of polyurethane molds, namely:![]() Polyurethane should not be less than 40 Shore hardness.

Polyurethane should not be less than 40 Shore hardness.![]() Stretching of a mold is from 600 to 800%.

Stretching of a mold is from 600 to 800%.![]() The mold should be able to sustain at least 800-1000 cycles (when working with concrete).

The mold should be able to sustain at least 800-1000 cycles (when working with concrete).![]() Precision of the relief allowing conveying the texture of the stone in the most expressive way is a must. It is usually texture blurring that indicates poor quality. It is often typical of the molds made of plastic.

Precision of the relief allowing conveying the texture of the stone in the most expressive way is a must. It is usually texture blurring that indicates poor quality. It is often typical of the molds made of plastic.![]() Exact geometry of forms is a requirement.

Exact geometry of forms is a requirement.

We produce molds for manufactured cement-based stone from high-quality polyurethane of 40 Shore hardness. The number of moldings (taking into account proper operation and maintenance of molds) is from 800 to 1000 cycles (for concrete products).

Molds are produced for both planar and corner elements.

High precision of Art-Stone Company polyurethane molds is obtained due to verified high-tech matrices. Our own technological laboratory with engineering staff allows us to develop any desirable stone relief in the shortest possible time.

You can see the video about our molds here.